Need more information, or thinking about working with us?

Advanced Automation Systems

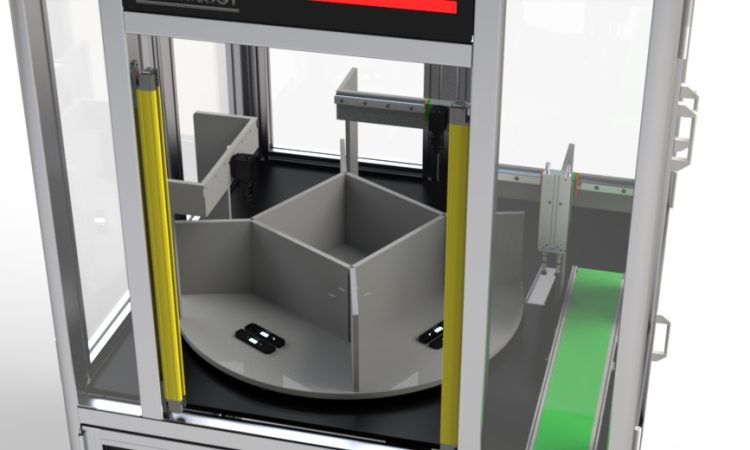

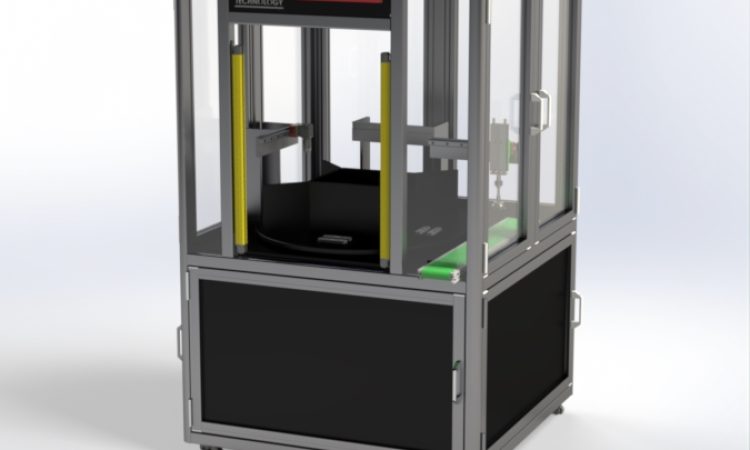

End of Line Testing Automation for Reliable Automotive Production

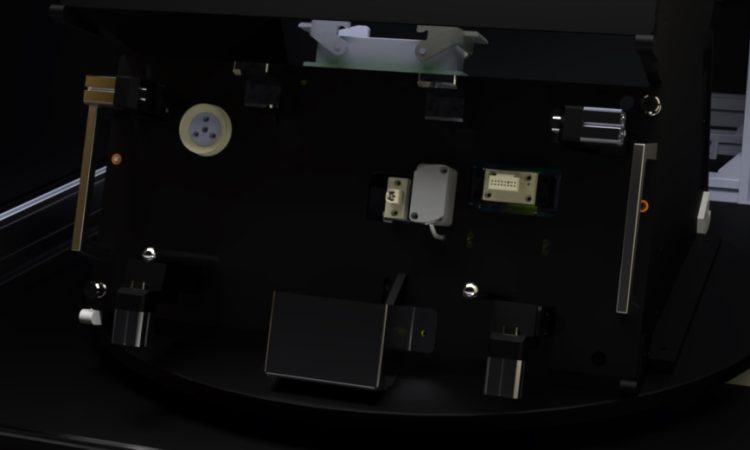

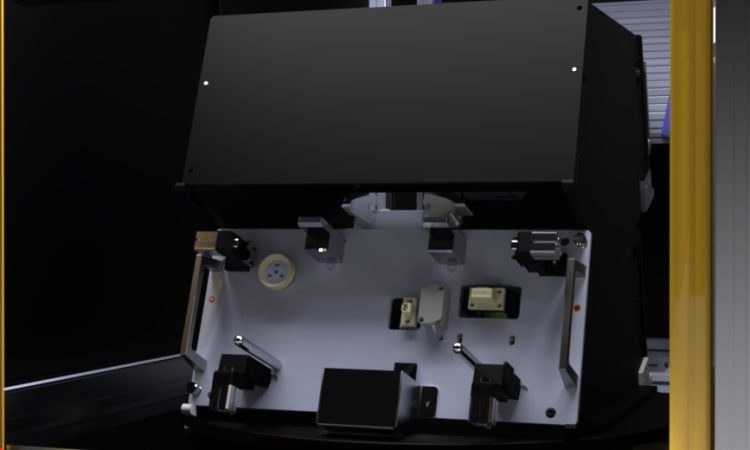

ALPHR Technology is proud to offer standard and special-purpose solutions to assemble and test a wide range of products for a variety of industry sectors. We have years of experience in End of Line Testing, supported by a team of dedicated engineers and directors to provide solutions to fit your business needs perfectly.

Bespoke Solutions

End of Line Testing is a critical process for many manufacturers, reducing errors and defects and improving the quality of products and services. ALPHR offers flexible, scalable assembly and testing solutions for many electronic products, including:

Control boxes

Instrument clusters

On Board Charging units (OBC)

Battery Monitoring Systems (BMS)

Battery testing

Motors and Inverters

PWM control valves

Solenoid valves

Rail network relays

In-car entertainment systems

Through constant development and innovation, ALPHR’s control platform provides industry leading data collection, product communication, traceability, and the creation of results algorithms, providing comprehensive, real-time analysis, enabling our customers to make informed, data-driven decisions.

By working closely with our customers to fully understand their specific requirements, ALPHR can provide End of Line Test solutions across a broad spectrum of testing processes, including:

PWM signal control

Current measurement

Voltage measurement

Frequency measurement

Leak and Flow testing

Programmable AC voltage control

Programmable DC voltage control

Bi-directional communication with various products

Resistance measurement

Speed of switching in relays

Drop-in and drop-out voltage/currents

Hysteresis measurements and calculation

If you have any questions about our electrical testing solutions, don’t hesitate to get in touch with ALPHR Technology today. Our team of experienced engineers is readily available to assist with any queries or provide detailed information, whether you’re located in the UK or anywhere else around the world. We take pride in offering prompt, reliable support and are committed to helping you find the right solutions to meet your specific needs.